A long time ago I had made a quilted jacket from a pattern I had used before. Funny, the other jacket fit perfectly and was so comfy. But for unknown reasons this time I was shocked to find this jacket was way too bulky for me in the shoulders and made me look and feel like a bear.

I didn’t like it at all, but I had put so much work into it I just couldn’t throw it away. Sadly I couldn’t figure out how or where to take it in to fix it.

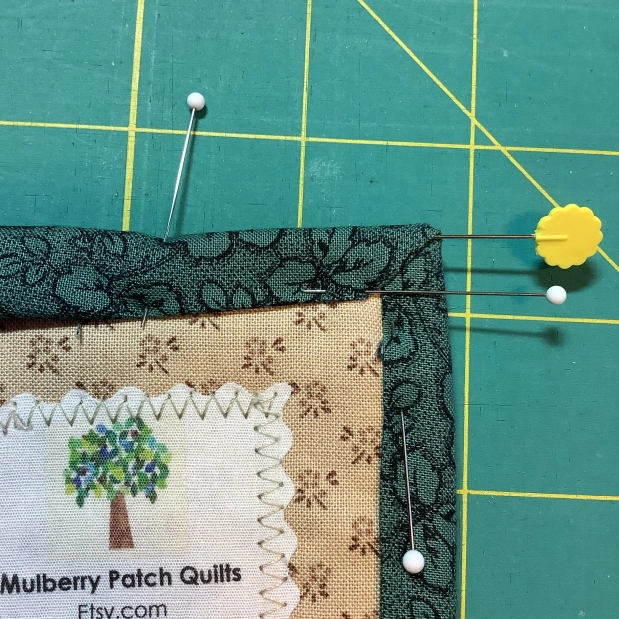

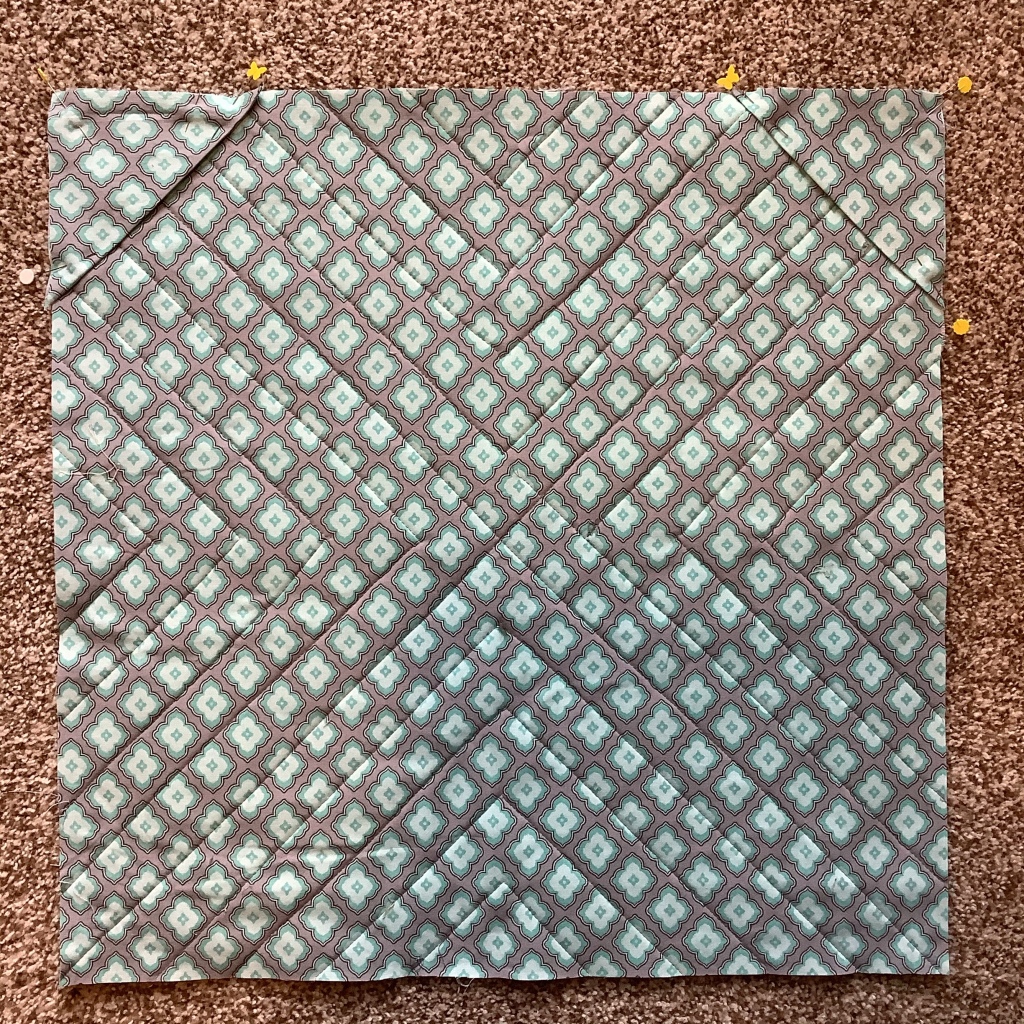

So it stayed, unused, in my closet for a few years. I never took a photo with it on, but you can see in the photo above and below how the shoulder seams are unflattering and the bulk at the bottom.

I couldn’t figure out how or where to take in the side seams or sleeves to fix the problems. So it sat in my closet. I never wore it.

Since quilted jackets are coming back in style, I started to think about making another quilted jacket and using one of the newer patterns. I researched jacket patterns on Pinterest and found several I liked, and finally chose one called the Tamarack Jacket.

Then it dawned on me—what if I used this new pattern to completely recut and reconstruct the jacket in my closet instead of starting over from scratch?

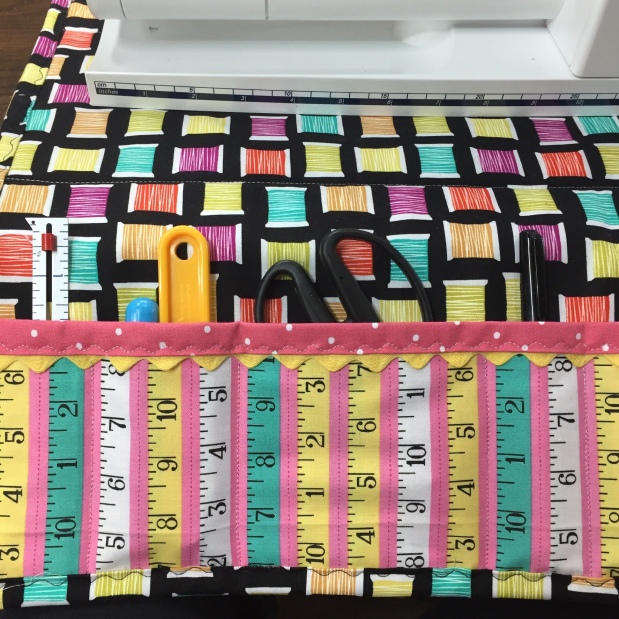

I wish I had taken more photos to share with you as I got out my seam ripper and went to work unsewing all the seams in the jacket I would never wear.

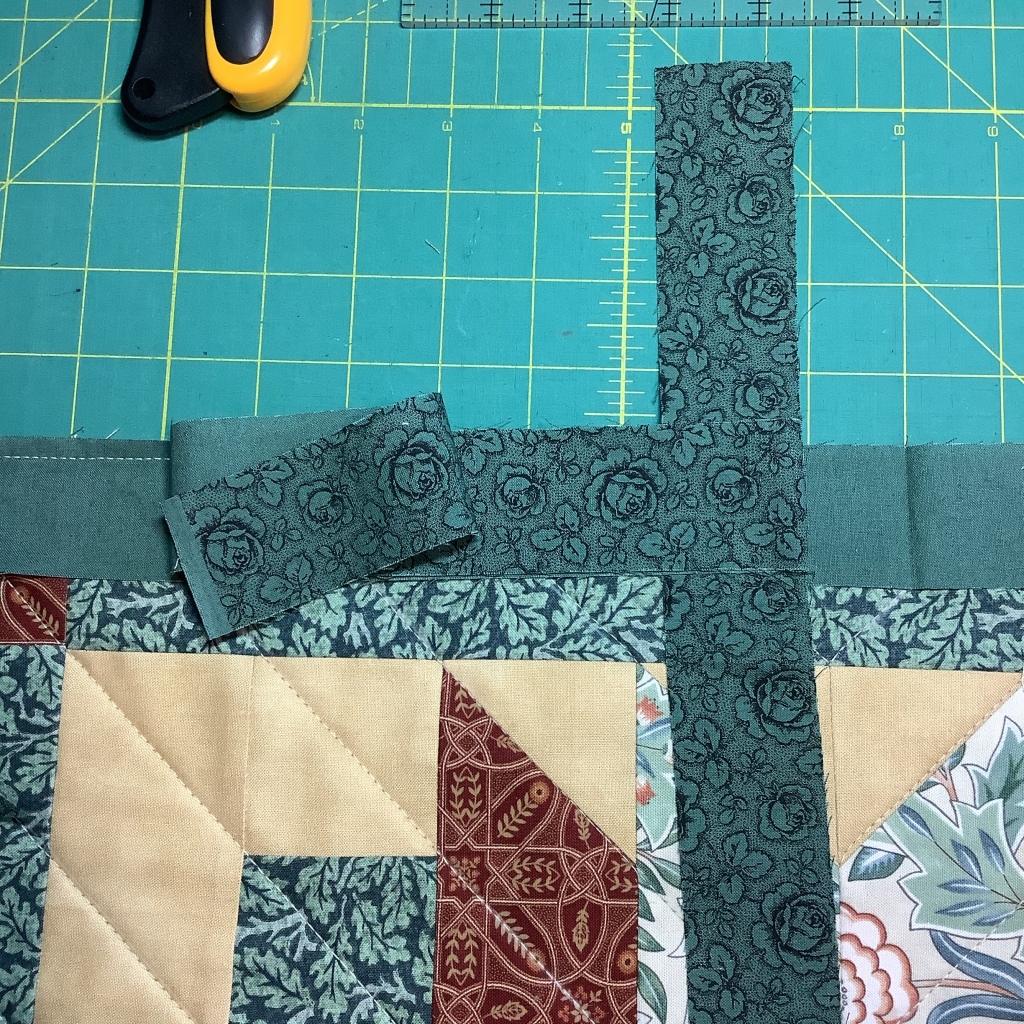

Here (above) are the remnants of the knit ribbing and some of the extra fabric cut off after recutting the new pattern pieces.

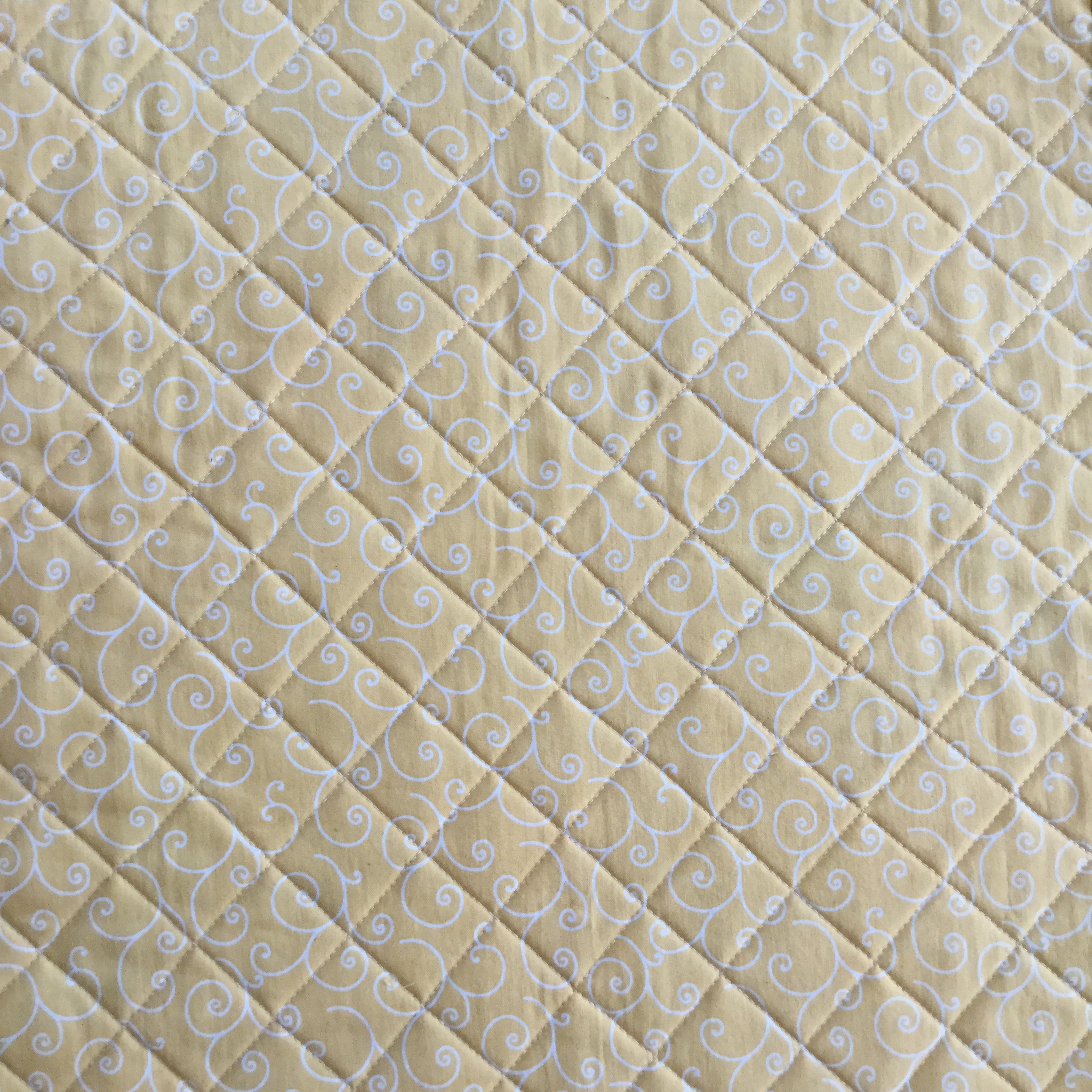

Because the jacket was too big, I had plenty of room to use the new pattern pieces to recut them. The only place I had trouble was the length. Since the original pattern featured knit ribbing in the collar, cuffs, and bottom, I had to create more quilted fabric to add to it.

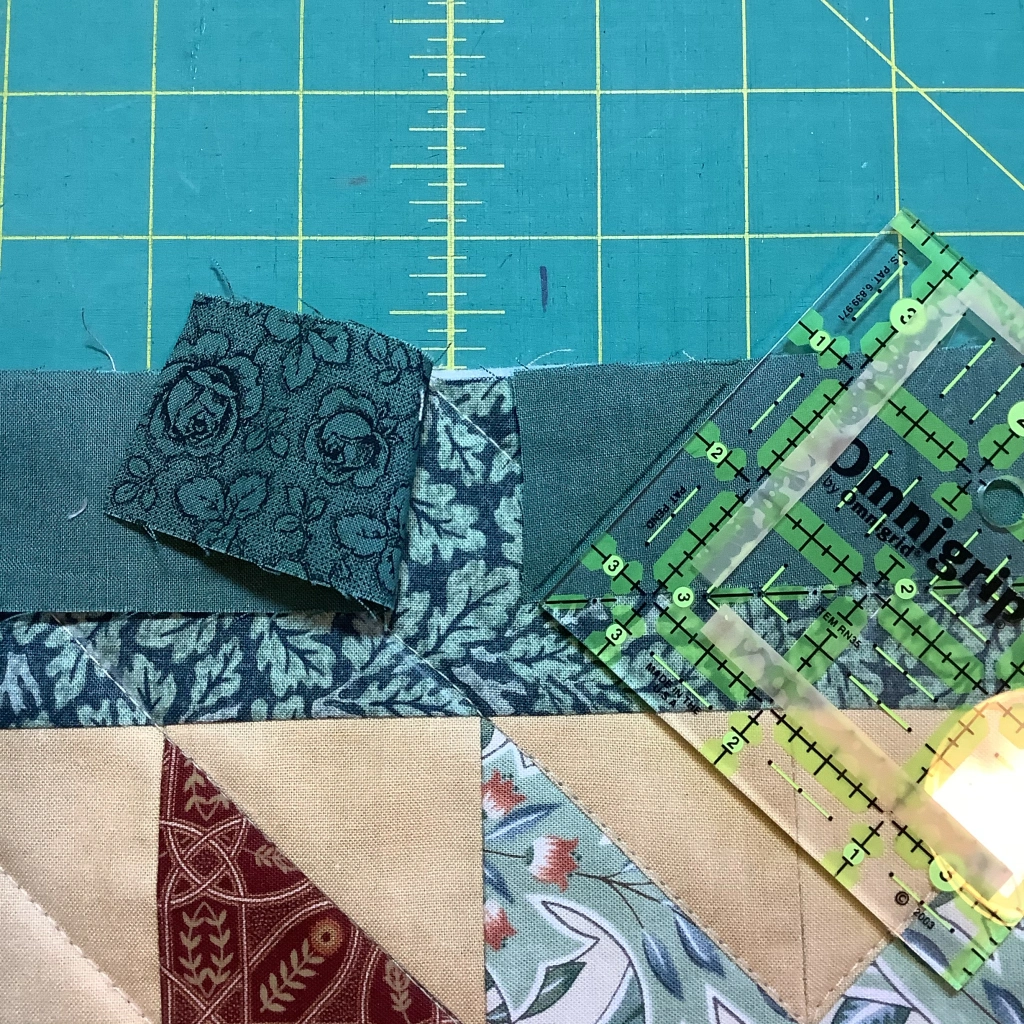

Luckily I had more of the coordinating batik fabric and was able to add lining & batting along with piecing strips together to make the sleeves the right length for the new pattern. But sadly, there wasn’t enough fabric left to lengthen the jacket so I chose not to add the pockets and make a shorter version.

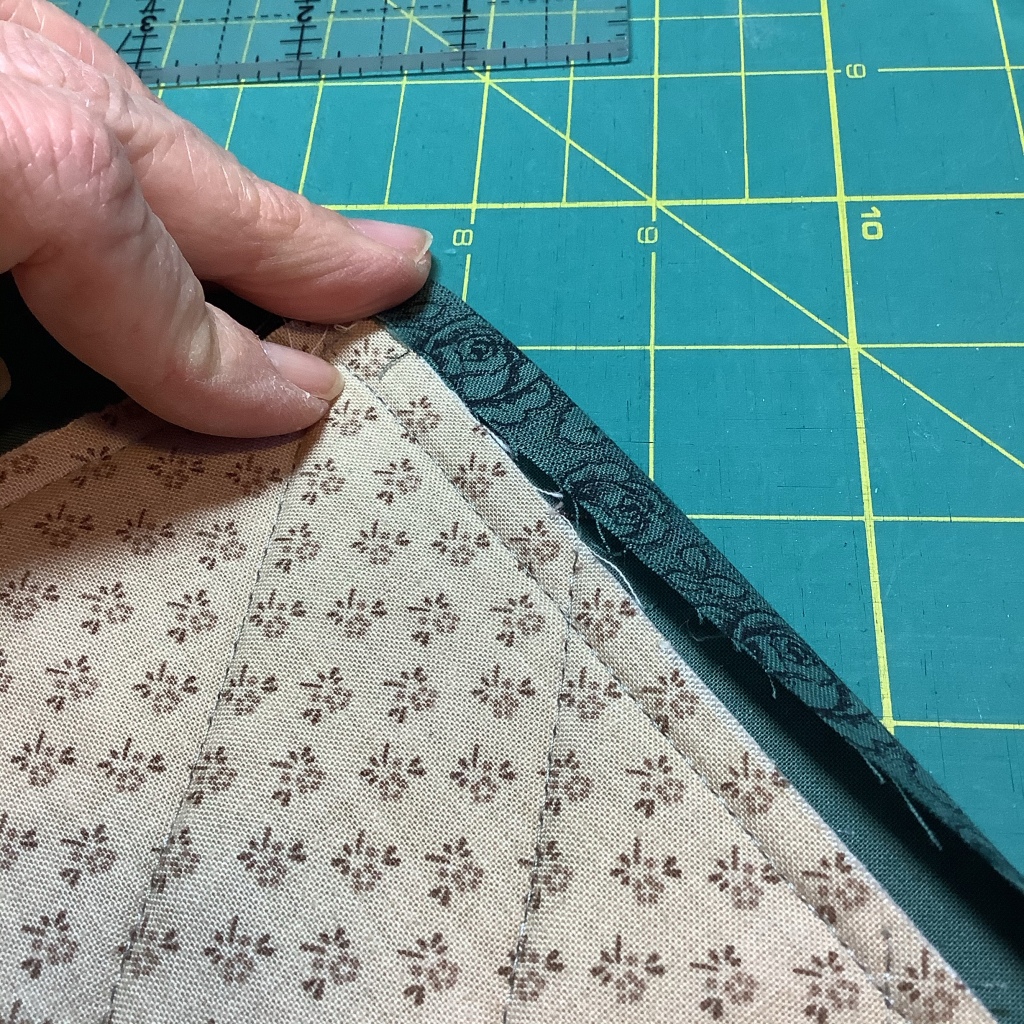

You can see the bands of coordinating fabrics I used to lengthen the cuff of the sleeves in the photo above and below.

All that’s left to do is add a separating zipper that I’ll topstitch down the front and it’s done. And although it’s mot perfect, it has been transformed into a better fitting jacket that I will want to wear!

I did a little “cat walk” video on my instagram page, which I can’t replicate here, but if you’re interested, you can view it at this link:

https://www.instagram.com/reel/CvdGKjupLIY/?igsh=MWgyOGlhdTdyczJjZw==

So if, like me, you’ve made a garment that doesn’t fit and it’s sitting in your closet, never worn, I hope this post might encourage you to salvage it by un-sewing and recutting/resewing it with a new pattern.

Until next time, HAPPY QUILTING!

Jane, Mulberry Patch Quilts